Modern Metal Carpentry: Innovation, Precision, and Custom Solutions

In recent years, metal carpentry has undergone a profound transformation thanks to the introduction of advanced technologies and innovative methodologies. This sector, vital to numerous industries, now demands the highest standards of precision, efficiency, and customization.

Cutting-Edge Technologies in Metalworking

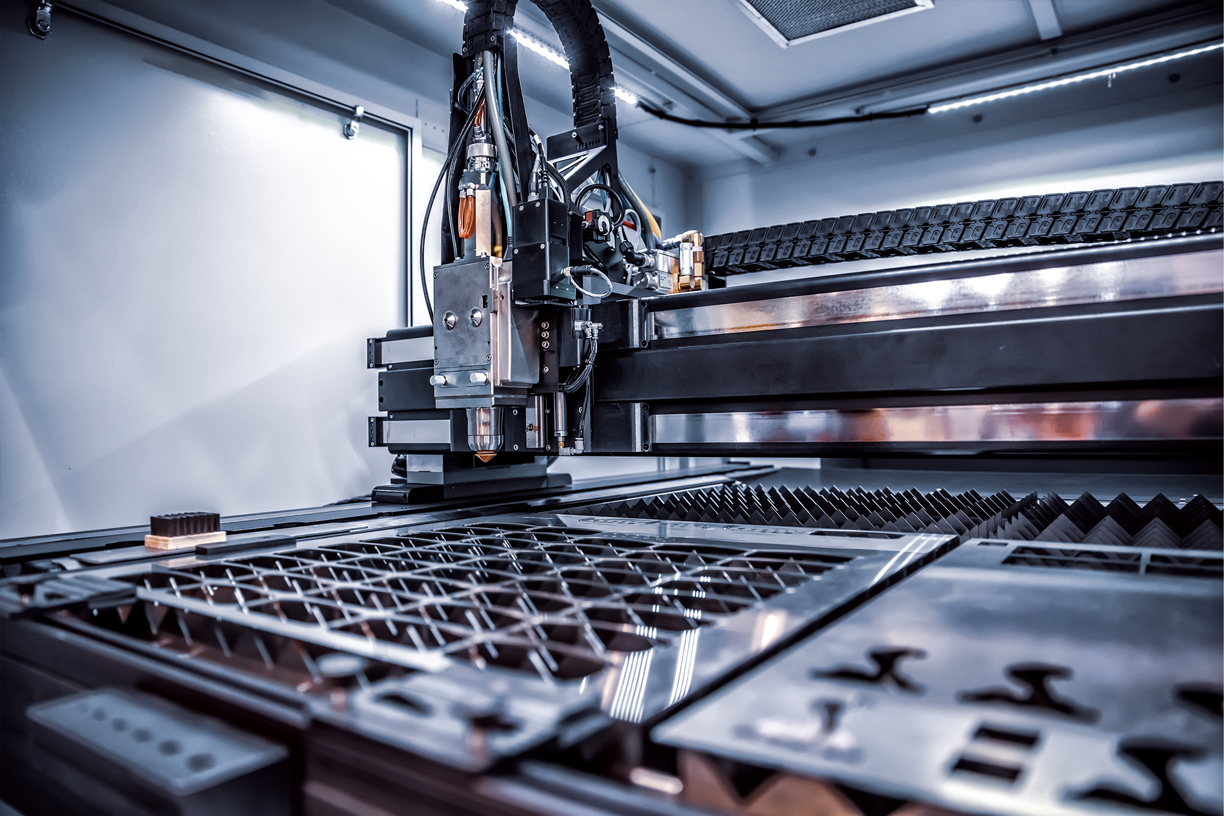

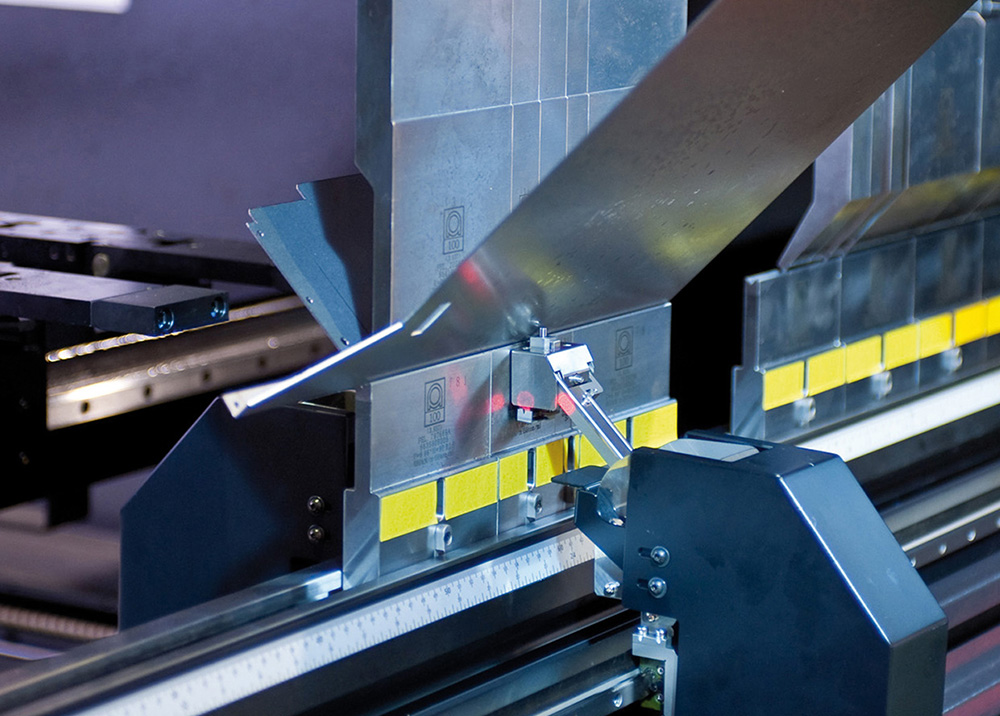

The adoption of next-generation machinery has revolutionized production processes. Among the most advanced technologies are:

- High-precision laser and plasma cutting, ensuring detailed work and minimal error margins

- CNC bending, providing accurate forming even for the most complex geometries

- Robotic welding, enhancing joint quality and reducing lead times

These tools not only streamline operations but also allow manufacturers to meet specific requirements with speed and reliability.

Customization and Flexibility Across Industries

From tailored design to the fabrication of complex structures, modern metal carpentry delivers bespoke solutions for a variety of industries:

- Agricultural: components for machinery and support structures

- Marine: corrosion-resistant metal parts for shipbuilding

- Construction: structural steel for large-scale infrastructures

- Energy: supports and frameworks for industrial installations

Innovation and Continuous Training: Keys to Quality

Investing in technological innovation and ongoing employee training is essential to address evolving market demands and maintain high-quality standards. The future of metal carpentry lies in agility, precision, and the ability to adapt to increasingly complex projects with customized, efficient, and sustainable solutions.